Why would anyone care about 3 phase power? Well if your only interest is residential power, then you won’t care, and don’t bother reading on. We’ll have some video instruction and posts for your application in the future. But if you’re considering alternate energy solutions for commercial and light industrial applications, then it’s worthwhile at least knowing your options. Being locked into single phase power for any commercial enterprise can be a problem down the road. If your business is successful and grows. particularly if growth means more heavy equipment, then having three phase power available opens the door for more efficient, less expensive, and more capable products. Having three phase power also makes it easier to balance your loads. It doesn’t make sense for residential power since the loads simply aren’t that heavy, but for a growing business, it could be a roadblock that leads to compromises that are expensive to undo.

There are numerous ways to build solar installations that accommodate 3 phase–if the installations are purely grid-tied. But if, like me, you have reasons to be concerned about mid-to long-term grid outages and want a reliable backup system your options are more limited, and can be extraordinarily expensive, complex, and limiting. There are 3-phase inverter systems available for commercial and light industrial use, but the cost is high, the installation is complex, the equipment is large and heavy, and upgrade paths are generally whatever a single manufacturer offers.

Single-phase hybrid systems designed for residential and light commercial use are becoming very attractive in price, features, capability, upgrade paths, and form factor. Hybrid used refer to systems that put MMPT solar controllers, battery chargers and inverters in one box. These were generally used for off-grid applications. Now it’s more often used to describe all-in-one systems that can support both off-grid and grid-tied applications. The 48V battery systems they utilize have all the volume benefits of widely implemented residential solutions. The systems can be paralleled to increase capacity to meet the requirements of any residential and many commercial single phase electrical systems, and some can accommodate three-phase systems elegantly. The application is not widely marketed, and no smaller systems offer this capability, but some of the larger hybrid systems that offer split phase 240V can be configured with two units operating together to accommodate three-phase. We’ve begun the planning process to install a capable three-phase hybrid solar power system at the Expert Amateur shop.

Our shop is unusual for a “hobby-level” shop (hence the Expert in Expert Amateur). It was built as a granite and marble cutting operation that went bankrupt in the credit crunch of 2007-2008. We bought it inexpensively from the bank in 2012 to house our myriad projects (yes, we know myriad means ten thousand, the picture below is just part of the shop–and now you understand). The electrical system is massive, built to power and manage heavy cutting, polishing, and fabricating equipment. The building looked like massive overkill for a “hobby” shop, and we’ve managed to fill it. We only have one, and potentially two three-phase loads–a huge rotary compressor that provides shop air, and a massive punch we bought with the intention of turning it into a power hammer for forming sheet metal. To give you a sense of the punch’s scale, it was previously used to punch square holes for the big carriage bolts that hold Armco highway barriers onto their mounting poles. One stroke=one hole. It’s scary, I’ve only run it once. In practical terms I don’t need to support three-phase power, but it’s what I’ve got. The shop is a considerable asset, converting it to single phase or adding a hybrid solar power system that only supports it as split-phase 220/110V would be a bit short sighted. So I started looking for solutions. The clever folks at Current Connected suggested an elegant solution–it turns out that both the Sol-Ark 15K and the EG4 18K hybrid units can be wired and configured to support three phase power–both on the grid and off-grid. Even more interesting, the configuration doesn’t require three units to support three phase, but only two. And the batteries can be combined as a single bank to supply the two inverters. There are other possibilities for ensuring the power is always available, such as connecting a backup generator for automatic starting. The remainder of this article will focus on the EG4 18K hybrid inverter but most of the features and functions apply to either system.

The EG4 18k is capable of being mounted outdoors, which is advantageous whether I decide to mount this system inside my shop, or on an outside wall, or in one of the two containers I already have on my property. Systems designed for indoor-only use have fans that blow directly into the electronics to cool them, which means dust and other contaminants may wind up in the system. The outdoor mounting system seals the electronics from dust and moisture and circulates air in a separate chamber to cool heat sinks that keep the electronics cool.

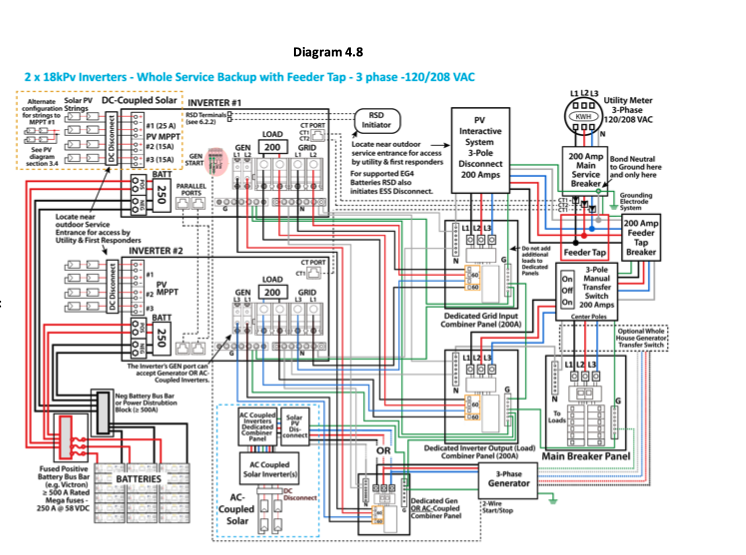

This rather complex looking wiring diagram and the associated configuration of the system is not quite as challenging as it first looks. Each of the EG4 18K systems have 3 mppt solar controllers built in, enabling 3 DC coupled series strings of PV panels to be connected with a series voltage of up to 450VDC. The drawing shows 4 strings connected to each inverter but two of the connectors are in parallel. For this 3-phase configuration that means 6 strings at 600V to a maximum of 18,000 watts per panel, 36,000 watts of PV total. The AC output is 12,000 watts each with a surge capacity of 15,500W for 5 minutes, so 24,000/31,000 watts total. The system intelligently handles battery charging and shifting charging load to off-peak grid.

The complexity at the bottom of the schematic to the right of the battery bank is optional stuff. There’s some AC coupled Solar, which might be a legacy microinverter system. To the right of that is a generator backup. Both the AC-couple PV and the generator feed a generator input connection. Super handy if you need that level of backup, but I don’t anticipate doing anything like that and I don’t have any legacy PV system at my shop. Depending on the contract my utility offers I may or may not backfeed the grid. Treating the grid only as a way to charge the batteries if necessary or supply additional power if the system can’t handle the total load further simplifies the system. If I can get a reasonable net metering agreement it may be worth the added effort and equipment, given the size of the PV panel system I anticipate, I probably won’t need the grid for much.

The remainder of the complexity deals with how you choose to connect to the grid. The simplest way is to backfeed a breaker on the main panel. This simple approach has some limitations and presents a few hazards but it is possible. The biggest limitation/hazard is that it can overburden the main breaker and feed line. If your panel is 200A and you are near the limits of the breaker,

A PDF of the manual as well as other supporting documents is available on EG4’s website. I’ve printed a copy of the 94 page manual to familiarize myself with the equipment. I haven’t finalized my decisions about which batteries to use, both wall mount and rack mount batteries are supported by the CANBUS communication network. EG4 makes wall mount batteries that seem particularly well suited for the system and they are a little less expensive than the rack mount batteries, but rack mounted batteries permit smaller incremental upgrade steps, and if a battery fails it can be easily swapped out. I expect I’ll probably opt for the rack mounts.

I have another strange notion, I’m considering mounting the entire system in one of the two 40-foot containers I have on my property and building a solar array on the container instead of on my roof. I’m considering making covering my roof with solar (I have a HUGE solar potential at my shop) a separate project. If I only do a single container-based system with the design I’m contemplating I can install a bit over 10KW worth of solar panels with the mount I’m considering. Fundamentally a steel frame attached to one edge of the container able to pivot. Standard 40 foot containers are 8.5 feet high. I think mine are high-cube versions which are the same length and width, but are 9.5 feet high. My rack will be 16′ by about 40′ which can hold 24 450W panels for a total of 10,800 W. I’ll make the rack in two pieces that can be joined to pivot together with long hasps on each end so the panels can be adjusted for sun angle over the seasons, and disconnected to lay flat on the container, with one half panel flat on the roof and the second hanging flat against the side. I need to fire up Fusion 360 and get the design work done.

My shop has a shed-style southern exposure roof section over an open storage area that is about 38′ X 40′ which could hold about about 48 panels and a saltbox style main roof that could hold at least twice that many in an east-west orientation. I’m itching to cover it with panels, but until I see what the local power company is offering for feed-in these days there isn’t much reason to get carried away. Some utilities, like HECO in Hawaii are running pilot programs that offer incentives for installing battery storage in return for access to the stored power during high demand. Absent some useful incentive I may just support all my shop loads and charge our electric cars independently of the grid.

I will be doing extensive video documentation of the system, most of the work I’ll do myself. I’m retired, and I have a lot of distractions in the hobbies I enjoy, but metal fabrication and electronics are two of those many hobbies.