“Nearly anything is really interesting if you go into it deeply enough.”—Richard Feynman

Historically residential solar installations were frequently sold as AC-coupled systems (microinverters or string inverters), using the grid like a storage device to yield a return on investment by reducing the amount of electricity you buy from the grid. While that is a worthy goal I think a better one is to also power your home or business even if the grid goes down. Common AC-coupled grid connected systems stop working when the grid goes down. The EG4 18K PV hybrid all-in-one inverters and associated batteries can power your home or business when the grid is down. The system captured my interest because it’s so flexible, expandable, and adaptable.

Disasters that leave millions of people and businesses without out power for days, weeks—even months have become common. Regardless of what you think about climate change anyone can see that it’s becoming increasingly important to not depend solely on the electrical grid. Without power, homes become unlivable and businesses can’t operate and face the loss of inventory that requires refrigeration. Any capability that demands access to fuel (including generators) becomes difficult or impossible. Solar can be a solution for many of these issues. I can’t justify my large-scale project on a simple break-even calculation based on the power cost from my utility. But it’s easy to justify based on grid reliability.

Does this matter to a DIYer building an off-grid system for a cabin in the middle of nowhere? Absolutely. The same system that can scale to handle commercial and industrial loads can also power an off-grid house or cabin and is much simpler to install than traditional systems with multiple components. I’m using 18Ks to build a system that scales from off-grid with light loads to three-phase, grid-connected with sufficient capacity to power my entire shop, charge 2EVs, and grow to meet future needs. The scale of my project is just the tip of the 18K iceberg. The system can easily scale to power mid-sized commercial and industrial enterprises. The first step–an off grid system, was virtually plug and play.

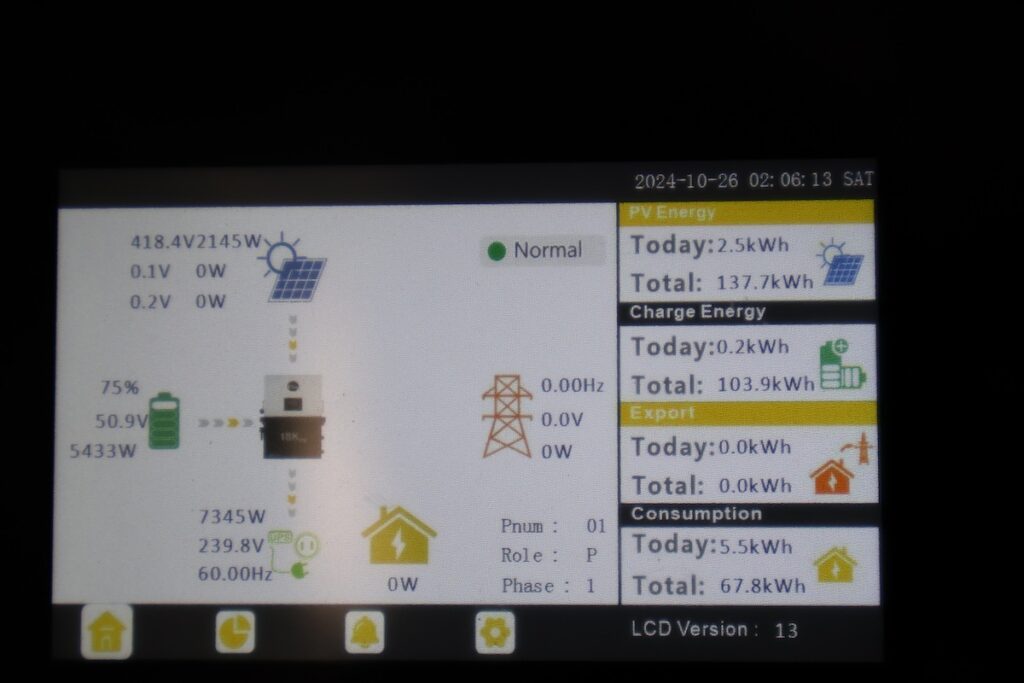

Here’s the 18K LCD screen showing the system charging my Tesla Model Y, delivering 30 amps at 240V, 7345 watts with 2145W coming from the PV panels (overcast day) and 5433W from the battery.

This first video in this series covers specifications—it’s an expansion of the information supplied in the 18K PV manual or the spec sheet available here: link. It’s may well be the most boring of the videos we’ll do, but the information is useful for building a system that meets your needs and budget. If you don’t want to watch a “speeds and feed” talking head video, the transcript is below. Here’s the video

The limitation of specifications is that they don’t tell you everything the product can do. Even the rest of the excellent 92-page manual can’t do that. It can tell you how to configure the product, but not how to use it. That’s up to you. Even something as simple as a pencil can be used in ways that go far beyond the purpose it was designed for. The 18k doesn’t require a deep dive to be interesting, it has so much capability that even a glance at the specifications is exciting for any tech geek. But there’s much more capability than that glance reveals, and the potential goes well beyond geekery. There’s huge practical potential both for managing PV systems—on and off-grid, and general applications like peak shaving and UPS.

One clarification. I have an affiliate relationship with Signature Solar. I make a small commission if you use the links I provide to purchase these products. That doesn’t affect the price you pay and doesn’t influence my purchase and use of these products, or my comments. I’m retired and I work at these projects to keep my brain functioning. I can afford my interests. If this equipment didn’t meet and exceed my requirements I wouldn’t bother with it.

In this first video of the deep dive series we’re going to cover JUST the spec sheet. We’ll do the configurations and options in future videos. We’re not going to cover mounting and basic wiring. The quick guide, manual, and various videos cover that in detail.

If you have an issue, correction, or question please comment on the video—I read every comment. I don’t promise to reply to every one but I want to hear your thoughts. I plan to try to explain almost every specification, setting, and function whether it’s obvious or not. Don’t take that as an insult to your knowledge, experience or intelligence. The manual and installation instructions are excellent. My purpose is to amplify and perhaps explain the instructions not replace them.

EG4 18K Specifications

AC INPUT DATA

Calling this “Input Data” is a bit confusing to anyone thinking of the system as mainly an inverter. I think this means the input to the power switching system which directs power from the inverter, the grid, and generator inputs. On the basis of user preferences the 18K manages power from the inverter, the grid, or generator input (which can be power from AC coupled PV systems that are already inverted to AC power) and delivers it to the loads. Power from the generator or ac-coupled PV power and the grid can also be used to charge the batteries according to preferences set in software configuration.

The system also preferentially manages DC power from the PV panels via the MPPTs to power the inverter or charge connected batteries, but this section of the specifications refers only to the AC management.

NOMINAL AC VOLTAGE 120/240VAC; 120/208VAC (L1/L2/N required).

The typical AC voltage delivered from the inverter is 120VAC with the output lines 180 degrees out of phase to produce 240V power. For example, when voltage on L1 is at +120V with respect to neutral L2 is at -120V, creating a voltage of 240V between L1 and L2.

The inverter can be configured for 120/208 VAC with each leg at 120 degrees out of phase. Because of that phase angle when L1 is at +120V L2 will be at -88V producing 208V.

With 120/208VAC 120 degree phase selected the system can produce a three-phase output from two or more synchronized units. While it is feasible to make three-phase power with just two units the available power per leg will be unbalanced (one phase will be supported by two legs while the other two will have one leg each). I’m told that even though the two-unit version is still shown in the manual it is not supported. If you want three phase, as I do, you should probably pony up for three units. It would be a pain in the ass to balance the loads in a two unit system anyway.

FREQUENCY 50/60Hz—the input and output frequency of all the AC power is configurable to make the system work more or less everywhere. The system can frequency shift to a slightly higher frequency to disable micro inverters or string inverters that are compliant with frequency control.

MAX. AC CURRENT 50A @ 240VAC—the maximum output current of the inverter. The current is the same if the inverter is configured for 208 V but the wattage will be less (208V X 50A = 10,400W).

MAX. AC INPUT POWER 12000W—maximum power at 240V (240V X 50A = 12,000W). Here’s where this gets interesting–Up to 10 18K PVs can be connected in parallel, which means the same system that can power a small cabin can deliver up to 120KW, which is enough power for many mid-sized businesses. It’s not entirely clear to me what the limit would be for three-phase systems. Most likely it’s nine paralleled units which would mean 104KW at 120/208VAC.

MAX. AC BYPASS 200A—allows the inverter to pass AC power directly from the grid to the connected load without going through the inverter’s internal circuitry. When the inverter is in bypass mode, it can allow up to 200 amps of current to flow from the grid directly to your load. If the load demands more power than the inverter can provide (up to 50 amps continuously), the inverter will switch to bypass mode, allowing power from the grid to meet the demand. 200 amps is generally the maximum size for a residential grid connection panel.

AC GRID OUTPUT DATA

This refers mostly to inverter output. Most of the specifications in this section have already been discussed except power factor, reactive power adjustments, surge capacities and harmonic distortion.

MAX. OUTPUT CURRENT 50A

OUTPUT VOLTAGE 120/240VAC; 120/208VAC (L1/L2/N required)

OPERATING VOLTAGE RANGE 180-270VAC

NOMINAL POWER OUTPUT @240V 12000W | @208V 10400W—208V times 50A is 10400.

OUTPUT FREQUENCY 50/60Hz

POWER FACTOR 0.99 @ Full Load—You may think that volts times amps equals watts, but for AC it’s really Volts x Amps x pf (power factor) where pf (power factor) is real power (watts)/apparent power (VA) or a bit more technically, pf=cosine of the phase angle between volts and amps. Any difference in the phase of current vs voltage means the peak of current and voltage will be occurring at different times (and therefore true watts will be less). Inductive loads (like motors) shift the phase of voltage vs. current making the current phase lag voltage phase. Capacitive loads shift the current phase to lead voltage, but capacitive loads are rare. The most common loads are resistive or inductive. Power factor is basically an efficiency rating that equates watts of power to VA (volt amps) accounting for the phase shift. This value in the specifications refers to the internal power factor of the inverter. Transformer based inverters generally have a higher internal power factor unless they do some kind of electronic voodoo that compensates for the inductive nature of the transformer. Other major league nutty stuff happens with big reactive loads.

REACTIVE POWER ADJUST RANGE (-0.8) ≈ (+0.8) Leading Adjustable—Since reactive loads cause current phase to lag voltage phase the real power (watts, the useful energy) is less than the apparent power. Compensating for the phase shift increases the real power. I don’t actually know how the 18K compensates for inductive loads. The usual way is to add big capacitors which shift the current phase forward. But the 18K apparently does it in software as a configuration that helps if you have frequent reactive loads. I’m not sure how that happens in software, I’m going with magic. Since I have no idea how this works I don’t know if this setting remains in force when your load is purely resistive. If it does, and your load is resistive, the compensation will reduce the real output power. A leading phase shift causes the exact same reduction as a lagging one.

MAX CONT. LINE WATTAGE 4000W—I’m not sure what this means since the maximum continuous output is 12,000W which should be 6000W per line for balanced loads.

PEAK POWER (SURGE CAPACITY) w/ PV: 14700W (10 min), 15500W (5 min)—My interpretation of this spec is just another guess. I think peak surge capacity is higher when PV strings are attached because the MPPTs are providing DC in addition to batteries. If battery voltage sags under heavy load because of the internal resistance and current remains constant the output wattage will decrease. PV power can keep the supplied voltage higher. Yes, I’m just guessing but it sounds good to me.

W/O PV: 13500W (10 min)

OPERATING FREQUENCY 50/60Hz

THD @FULL LOAD <5%—THD is Total Harmonic Distortion which is the noise in the output waveform at full load. Noise from switching or other processes affects the performance of some equipment. The amount of noise in the output waveform tend to be maximum when the system is fully loaded since all the components are being pushed to their max. Less than five percent is very good which means your 18K PV is unlikely to damage equipment you connect to it, even when the system is at or close to maximum output.

TRANSFER TIME 20ms (Default), single system: 10ms (Configurable) | Parallel systems – 20ms—This is the amount of time the 18K takes to switch from grid power to battery power. The rapid switching is the main reason this system is suitable for use as an uninterruptible power supply (UPS) for sensitive equipment. The quick response helps ensure continuity of power for most household appliances and electronics. For perspective, consider that 60 cycle AC passes through zero volts 120 times per second and all your equipment and appliances live happily with those interruptions. 20ms means the power might go to zero for .020 seconds–roughly one of those 60 cycles per second will look a little strange. Your most sensitive gear will never know it happened

BACKUP/UPS AC OUTPUT DATA

Using the system primarily as an uninterruptible power supply is partly a matter of perspective and partly a matter of configuration of how the system takes over if the grid goes down. The transfer from grid to battery power is covered above.

RATED OUTPUT CURRENT (240/208VAC) 50A

AC BYPASS (GENERATOR) 90A—this is in addition to the 50A from the inverter and can be from a AC coupled PV system or a generator so the maximum available output of the system with either a generator or AC coupled PV is 140A at 240V or 33.6KW.

NOMINAL OUTPUT VOLTAGE 240 | 120/240 | 120/208VAC

RATED OUTPUT POWER @240VAC 12000W | @208VAC 10400W

MAX. CONTINUOUS LINE WATTAGE 8kW per 120V—I assume this relates to the ability to deal with unbalanced loads. Since the total max wattage is 12KW, 8KW power per 120V line probably means the other line is at 4KW. That’s one heck of an imbalance but I’ve read elsewhere that the 18K can handle fairly extreme imbalance levels.

PEAK POWER w/ PV: 14700W (10 min), 15500W (5 min)

W/O PV: 13500W (10 min)

OPERATING FREQUENCY 50/60Hz

THDV (TOTAL HARMONIC DISTORTION VOLTAGE) <5%—

SWITCHING TIME 10ms—the system has a transfer switching capability. We’ll get into the anti-islanding features (avoiding backfeeding the grid when it’s down) in later videos and transcripts.

PV INPUT DATA

While the 18K has three MPPTs it actually has four pairs of PV input terminals

NUMBER OF MPPTS 3

INPUTS PER MPPT 2 (MPPT 1) | 1 (MPPT 2) | 1 (MPPT 3)

MAX. USABLE INPUT CURRENT 25A (MPPT 1) | 15A (MPPT 2) | 15A (MPPT 3)—The 18K MPPTs are very cool. #1 accepts parallel inputs up to 25A at up to 600V though nothing good happens above 500V, which means you can connect two series strings of about 12 panels each to MPPT1. Most currently available high performance PV panels are about 10-12A at 40-42V which means about 20A at 480-500V. Of course you need to make sure you’re less than 600V for low temperatures by doing the temperature coefficient calculations and its a good idea to leave yourself some head space, especially since you have two more MPPTs. It makes sense to size your series strings to deliver about 360VDC since that’s probably the sweet spot (so about 4000 watts per string). The recommended maximum PV input is 21000 watts which would mean five strings to max it out. There’s only 4, so toss in another panel per string if you want to hit that. The two parallel strings connecting to MPPT1 should be all the same panels of the same age, pointed in the same direction. A restriction that doesn’t apply to the remaining two MPPTs. The ability to connect two additional strings that would not play nice in parallel with string 1 is a lovely bit of future proofing.

MAX. SHORT CIRCUIT INPUT CURRENT 31A (MPPT 1) | 19A (MPPT 2) | 19A (MPPT 3)

DC INPUT VOLTAGE RANGE 100-600 VDC

UNIT STARTUP VOLTAGE 100 VDC

MPPT OPERATING VOLTAGE RANGE 140-500 VDC–It’s a good idea to keep your series strings under 500V to ensure the MPPT is operating in its sweet spot, and if you prefer connecting panels in parallel for some antiquated reason the 18K is not for you. You need 100VDC from the panels to wake the MPPTs up and 140 VDC to let them operate properly.

NOMINAL MPPT VOLTAGE 360 VDC–and there’s our probable sweet spot.

MAXIMUM UTILIZED SOLAR POWER 18000W—you can over-panel the 18K and it will use the added power to charge your batteries, but the maximum from the inverter is 12KW. More panels will do you good in overcast or mornings and evenings, but the most PV power the system can use is 18KW. It says so right in the name.

RECOMMENDED MAXIMUM SOLAR INPUT 21000W—even though the maximum amount of solar power the 18K can use is, well, 18K, you can gain some benefits from over-panelling the inverter up to 21000W (specifically, any time the panels are not being driven to their maximum output—like overcast days, and morning or evening sun—over-panelling may hold the output closer to the maximum). The excess when panels are at full power will get “clipped” (not used) but won’t cause damage. You can probably exceed this amount but may reduce the life of the inverter.

EFFICIENCY CEC 96.9%—California Energy Commission efficiency is a weighted average of output under various conditions. It provides a more real world value of efficiency than maximum efficiency.

MAXIMUM EFFICIENCY (PV TO GRID) 97.5%

MAXIMUM EFFICIENCY (BATTERY TO GRID) 94%

MAXIMUM EFFICIENCY (PV TO BATTERY) 99.9%

IDLE CONSUMPTION (NORMAL | STANDBY MODE) ~70W | ~18W—the amount of energy the inverter consumes while operating or in standby mode. The 18W standby is excellent.

BATTERY DATA

It’s not explicitly stated (as far as I can find) how many batteries the 18K can handle, it looks like a battery communication issue more than an 18K PV issue since the only requirement of the inverter is that one battery be master and the rest slaves (kinky). The EG4 all weather wallmount battery I’m using has a DIP switch that determines the battery communication address with the Master battery having ID1. There are a total of 64 settings, so I guess you can have 64 batteries talking to one EG4 18K. So 64 x 14.3KWh = 950KWh. Almost a megawatt. That should be enough.

COMPATIBLE BATTERY TYPES Lead-acid/Lithium—while the overwhelming number of installations will probably be Lithium, the 18K does support lead acid batteries. There are currently no lead acid batteries with closed or open loop communications, so the feature set is reduced. In some cases Lithium batteries that have incompatible communications or none at all will work better if the system is configured for lead acid operation, but don’t expect everything to go perfectly smoothly. Like any hack, the result can be a bit random.

MAX. CHARGE/DISCHARGE CURRENT 250A–that’s 12,000watts at 48V. I’m sensing a theme.

NOMINAL VOLTAGE 48 VDC

VOLTAGE RANGE 40-60 VDC (Lithium); 40-60 VDC (Lead-acid)

RECOMMENDED BATTERY CAPACITY PER INVERTER >200Ah

GENERAL DATA

MAX. UNITS IN PARALLEL 10–While that seems like an upper bound for what the system can power, I can’t think of a reason you couldn’t have multiple systems. Unless I decide to get serious about mining bitcoins (not likely), speculating about that feels a bit ridiculous. If I need more than 120 KW I’d probably build a nuke plant.

PRODUCT DIMENSIONS (H×W×D) 34.3×20.5×11.2 in (870×520×285mm)

UNIT WEIGHT 121 lbs. (55kg)–I installed mine myself, using a couple of pulleys. I don’t recommend that.

DESIGN TOPOLOGY High Frequency – Transformerless–Transformerless inverters use high-frequency switching, typically with MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) or IGBTs (Insulated Gate Bipolar Transistors) to synthesize a higher-frequency AC signal, which is then processed back into standard-frequency AC suitable for household appliances or grid use without the use of traditional transformers. Don’t confuse Transformerless Inverters with cheap high frequency inverters. The output of EG4’s line of transformer-less hybrid inverters is true 50 or 60 cycle AC sine wave with less than 5% Total Harmonic Distortion depending on how you configure them. I’ve looked at the output on my oscilloscope–it’s pretty, a nice, clean sine wave.

Since the output AC wave is synthesized the voltage, phase, frequency, and power levels can all be configured by software that manages the MOSFET switches. This ability to synthesize the output and control it with software figures greatly in the capabilities.

While transformerless inverters offer many benefits, they lack the inductive isolation between the DC and AC sides that traditional inverters offer. This makes grounding and lightning protection more important.

RELATIVE HUMIDITY 0-100%

OPERATING ALTITUDE <2000m (<6561ft)–People freak out a bit over the altitude spec. Really, most power electronics have a similar spec due to cooling limitations. Less dense air doesn’t cool as well. You can still use the equipment in the mountains, but you probably should downgrade how much power you pull through it.

OPERATING AMBIENT TEMPERATURE RANGE -13°F – 140°F (-25°C – 60°C)–Heat kills electronics. If you choose to mount the system outdoors in the sun you might consider either shading it or painting it bright white.

STORAGE AMBIENT TEMPERATURE RANGE -13°F – 140°F (-25°C – 60°C)

NOISE EMISSION (TYPICAL) 68dB @ 3ft–cruising along at moderate power the system is spooky quiet, but when you max it out expect to hear the cooling fans blasting. It’s not egregious, but it’s not 68dB. When I charge my Tesla it sounds like a drone is trying to take off in my container.

COMMUNICATION INTERFACE RS485/Wi-Fi/CAN

STANDARD WARRANTY 10-year standard warranty

OUTDOOR RATING NEMA 4X–a rating for outdoor electrical enclosures that provide protection against corrosion, windblown dust and rain, splashing water, hose-directed water, and damage from external ice formation. 4x vs plain vanilla Nema 4 adds corrosion protection.

SAFETY FEATURES

PV Arc Fault Protection–Arc fault circuit interrupter AFCI that detects arc from connectors coming loose or insulation failure between parallel wires

PV Ground Fault Protection–GFCI prevents shocks from ground faults.

PV Reverse Polarity Protection–diodes or MOSFETS that prevent component damage from accidentally connecting the positive and negative terminals backwards.

Pole Sensitive Leakage Current Monitoring Unit–monitors leakage currents to detect faults and provide protection

Surge Protection Device–protects from damage due to voltage spikes caused by lightning strikes, utility switching operations, and other transient events.

Output Over-Voltage Protection–shuts down or clamps the output when the voltage exceeds a preset level.

Output Over-Voltage Protection Varistor–probably an additional OVP device that shunts spikes to ground.

Integrated Disconnect DC switch for each MPPT–very nice, and if you mount the system outdoors and post a sign pointing out the integrated PV disconnect so first responders can see it you’d probably pass inspection without adding an external PV disconnect switch unless your inspector is having a bad day.

STANDARDS AND CERTIFICATIONS

Ul1741B Rule 21–Required in California and Hawaii, UL 1741 SB requires comprehensive testing for advanced grid support functions and interoperability

Rapid Shut Down (RSD) NEC 2020:690.12–RSD reduces shock hazard for firefighters. On triggering the RSD, controlled conductors outside the PV array must be reduced to less than 30V within 30 seconds. Inside the array the voltage must be reduced to below 80V within 30 seconds. There are a lot of exceptions to the requirement but an RSD is nice to have and the 18K has both an RSD switch on the unit and provision for installing an external RSD button.

Arc-Fault Circuit Interrupter (AFCI) NEC 2020:690.11 / UL1699B–detects and interrupt arcs due to series circuit openings in the DC PV circuits. This is intended to prevent fires from faulty PV connections or breaks in the wiring.

Ground Fault Monitoring (GFDI) NEC 2020:690.41(b)–Detects ground faults to prevent electric shocks and electrocution. Works by detecting imbalances greater than 5 milliamps between the current flowing in the hot and neutral wires.

CSA 22.2.107.1–Canadian standard requiring inverters to cease energizing the grid within 0.1 seconds upon loss of the grid supply.

CSA 22.2.330–Another Canadian standard. I can’t locate any reference that explains this standard but it might have something to do with RSD.

IEEE 1547.1:2020–testing requirements and procedures for smart inverters and other grid-interactive equipment

IEEE 1547:2018–I thought “OK, it’s just the older spec”, but no. It specifies voltage and frequency ride-through capabilities, active voltage regulation, frequency shift response, reactive power control modes, and interoperability and communication requirements

Hawaii Rule 14H–inverters must meet rule 14H requirements to be connected to the grid in Hawaii.14H is a lot like California Rule 21 in that it enables utilities to manage grid connected systems better. It also ensures that inverters are compatible with some of the unique characteristics of Hawaiian grids.

California Rule 21 Phase I, II, III–Because of course California has special requirements. Rule 21 is being implemented in phases. It’s great that the 18K already meets phase III. Basically any solar project applying for grid interconnection has to have advanced autonomous grid support functions and must be certified under UL 1741 Supplement A (SA). Qualified inverters must communicate with each other and utility systems over the internet using specific protocols to enable data monitoring, remote connection and disconnection, maximum power controls, and other functionality. The requirement enables some desirable programs like battery sharing and increase the value of energy generated by non-utility solar projects.

FCC Part 15, Class B–concerns RF emission of Class B devices. Class B is basically consumer electronics. Compliance ensures that the 18K does not cause harmful interference to other devices.